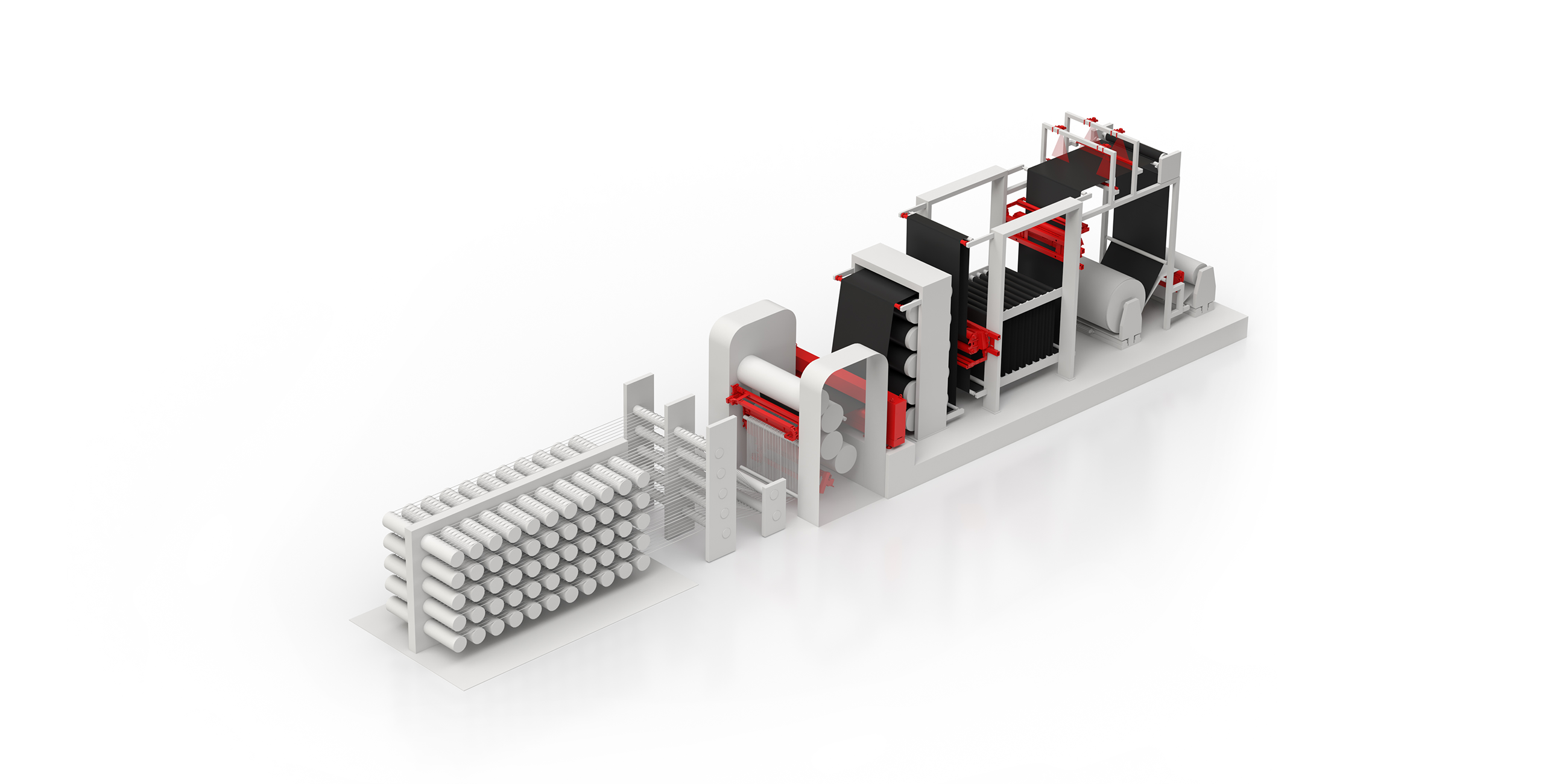

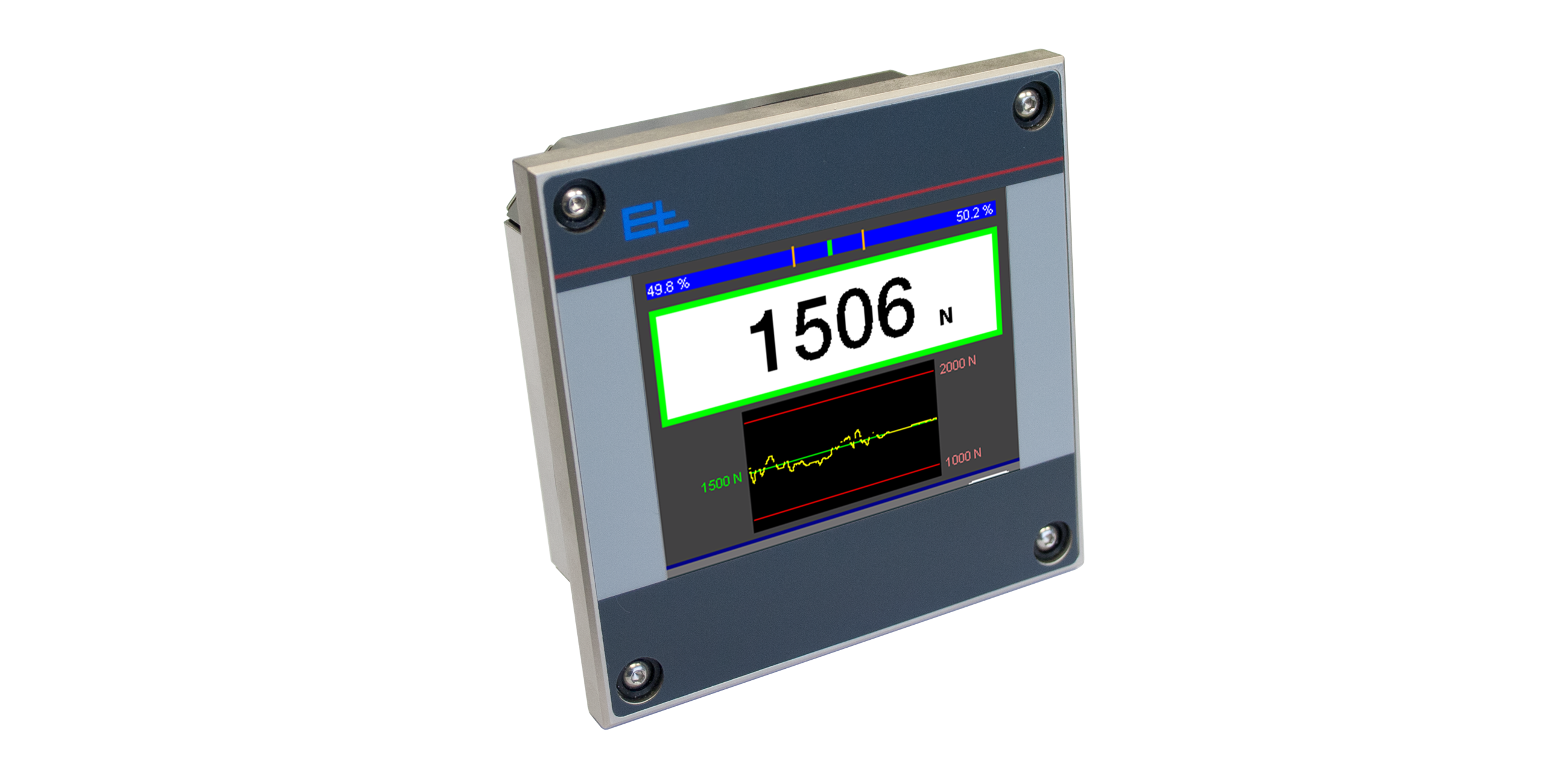

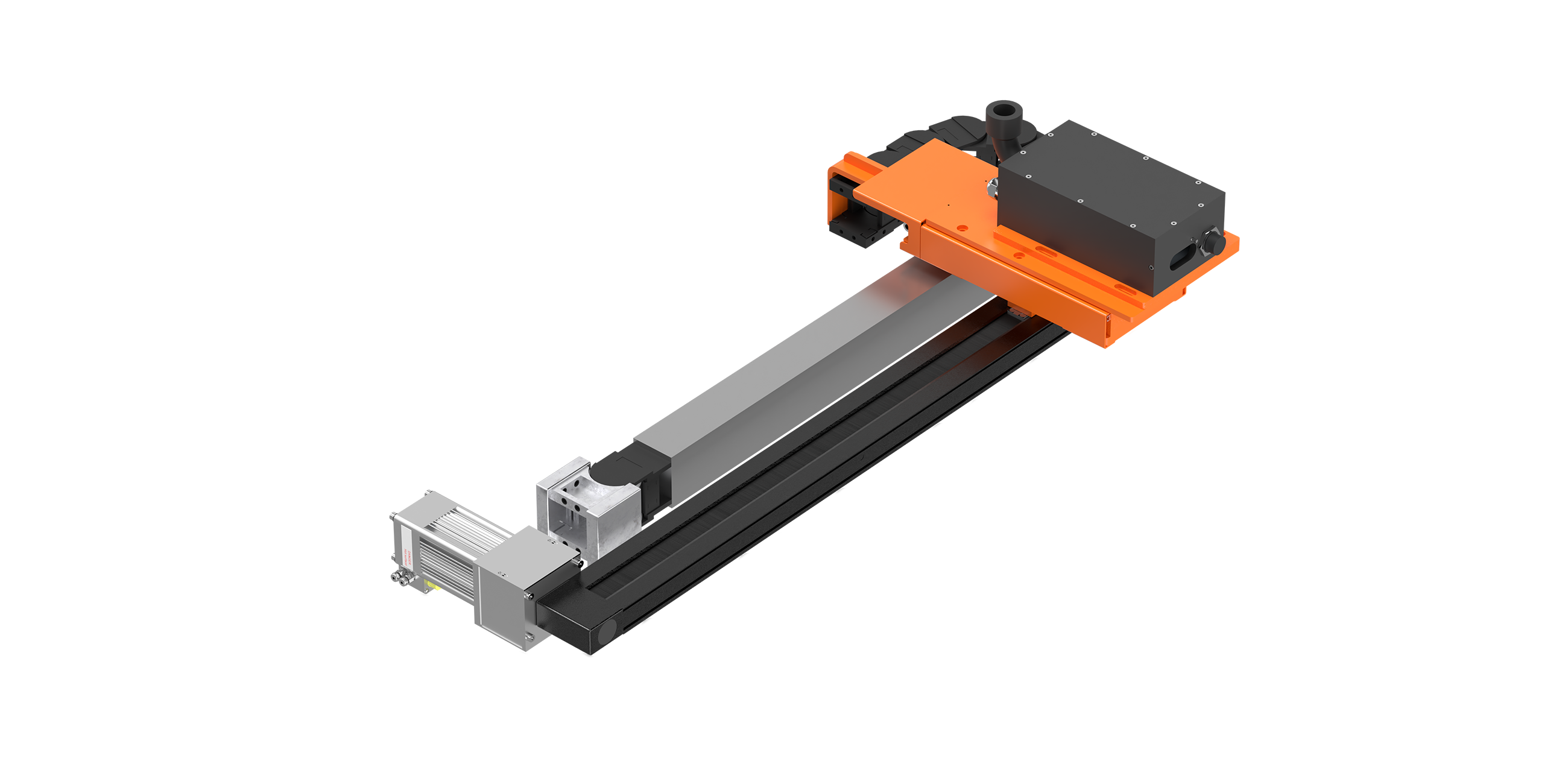

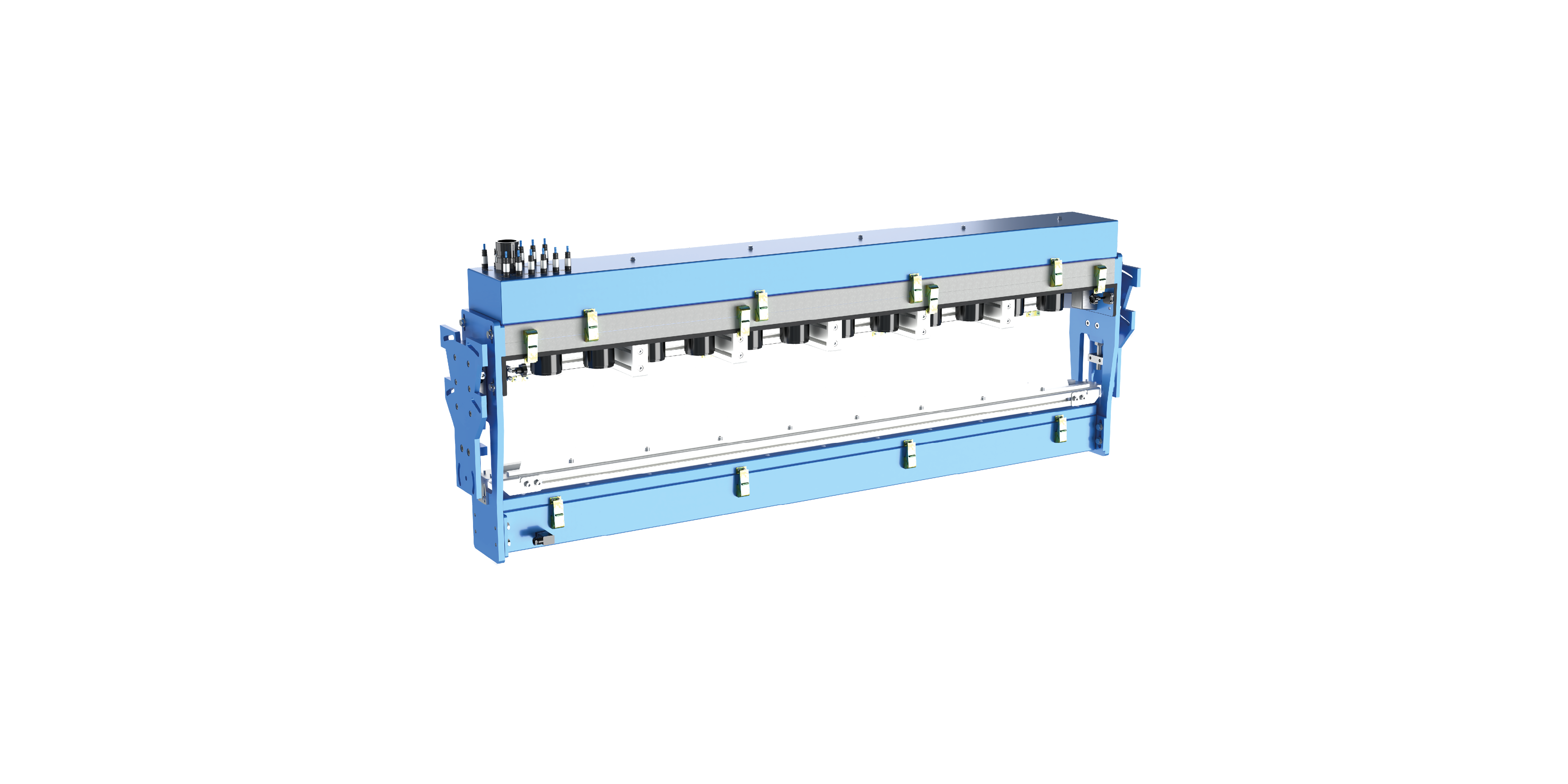

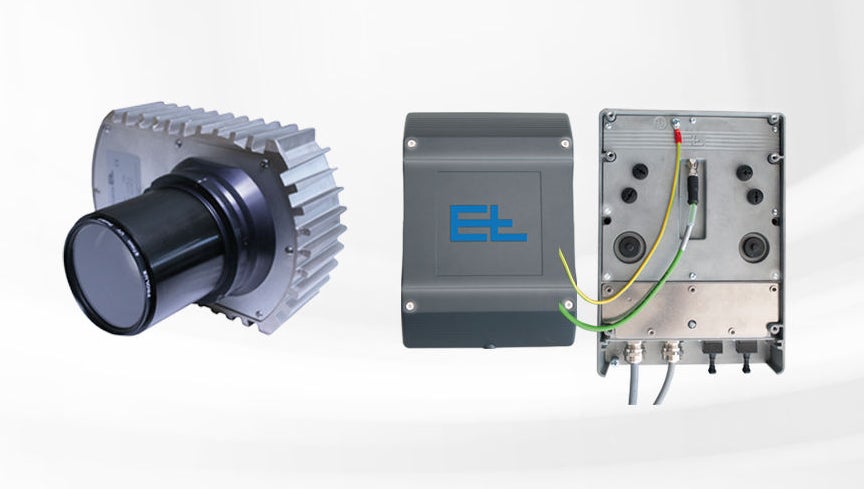

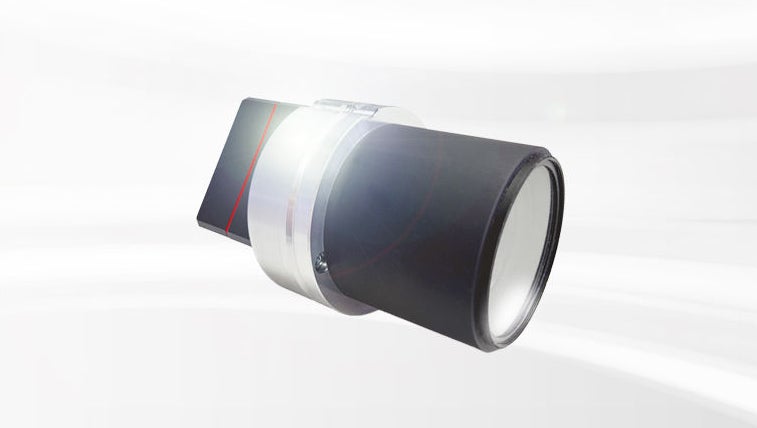

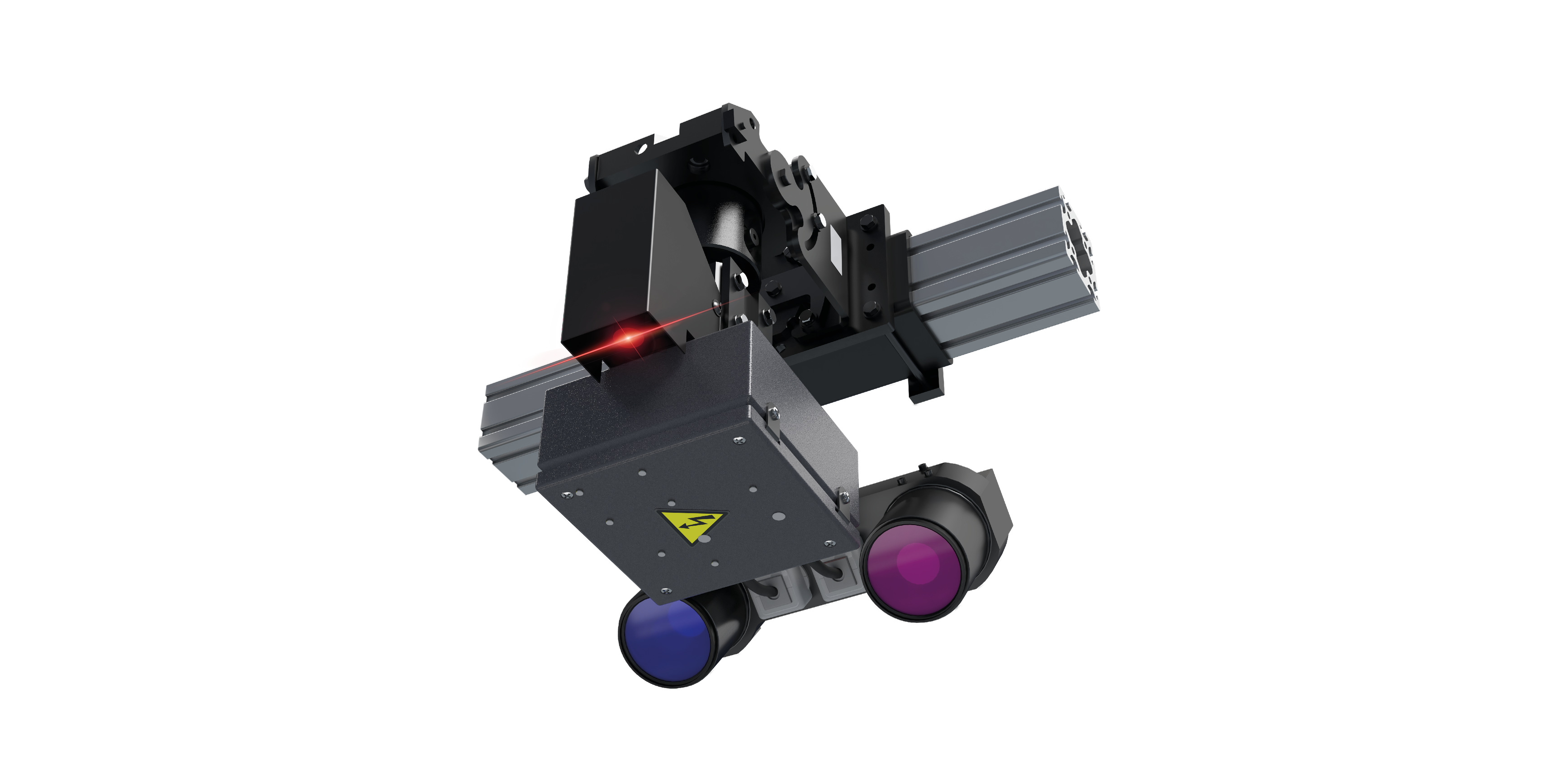

En las líneas de calandria, los alambres de acero se introducen en una calandra, que los recubre con varias capas de caucho. Esto crea una trama de cordón y goma infinitamente larga. E+L suministra todos los componentes para mantener las bandas producidas en posición, para cortar y laminar otros materiales y para medir el espesor. Así se cumplen los más altos estándares de calidad.